Say hello to the Dunkbot! Reveni Labs has launched an exciting Kickstarter aimed at film photographers who want an easier and faster way to develop at home. Designed by Matt Bechberger, founder of Reveni Labs, the Dunkbot is a circular automated processing system for 35mm, 120, and even 4×5 sheet film. It regulates temperature, timing, and agitation while also being able to perform multiple cycles in a row.

The Kickstarter campaign is running until Sunday, April 16, 2023, at 8:16 PM BST.

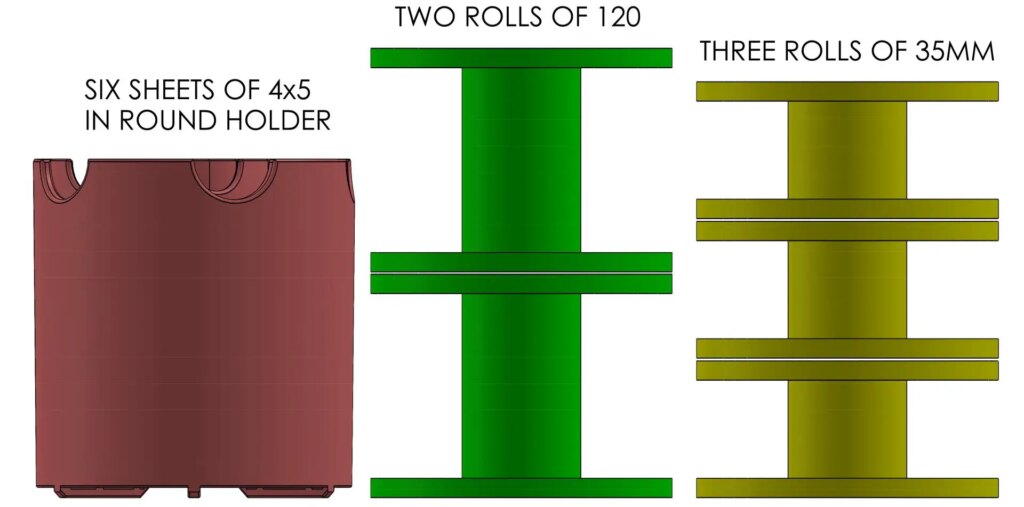

Initially, the design for the Dunkbot did not include 4×5 capabilities but after post-launch feedback from the community, Matt altered the design so that the Dunkbot could process 4×5 film. Users will need to purchase a special 4×5 sheet holder as none are included but these are commonly available from third parties. With this upgrade, capacity was increased to either 3x 35mm films, 2x 120 rolls, or 6 sheets of 4×5 negatives.

Matt wanted to create something for film photographers that offered an at-home solution but took on the labour-intensive demands of home developing.

Home developing gets you fast results and saves you money, but it requires manual labour and careful attention to detail. Mail-order developing is convenient, but the results can take weeks, and shipping to and from the lab increases costs significantly. – Matt Bechberger, Reveni Labs

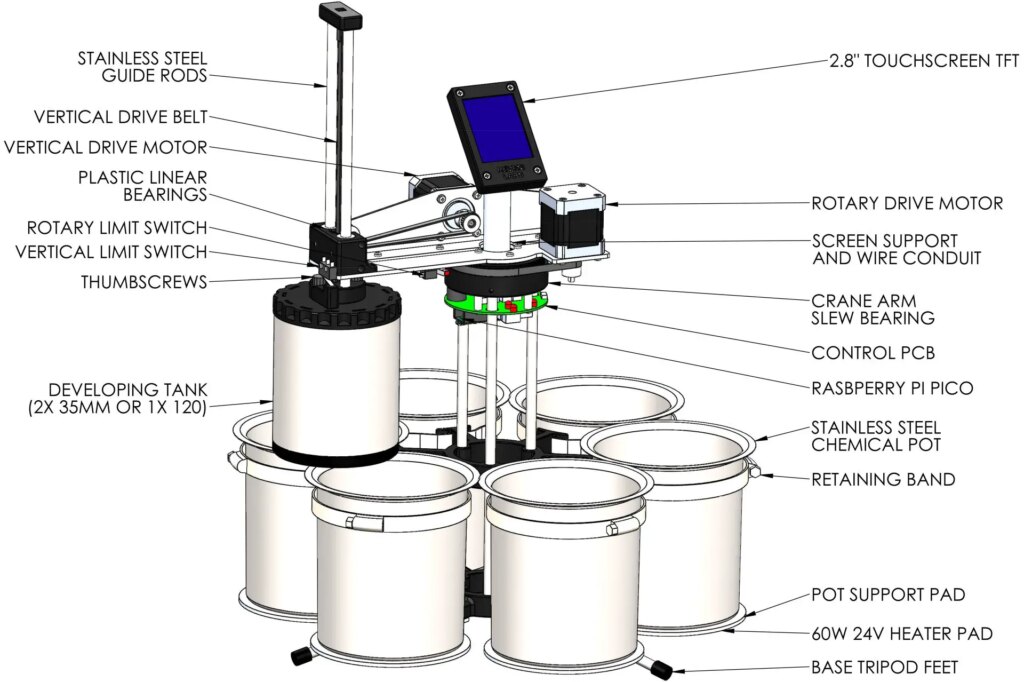

The Dunkbot uses a dip-and-dunk design to move the film through different liquids while automating temperature control, timing, and agitation. Having a six-liquid capacity, it allows photographers to use a range of chemical processes such as black and white, C-41, E-6, and ECN-2.

Matt says, “Dip and dunk is a classic method for mass-processing, and was widely used before the mini-lab was invented. The original dip and dunk machines were massive machines and handled many rolls hung in strips. It turns out a small dip and dunk machine is how analogue photo-booths work as well. I did not know this before designing my machine, someone mentioned it to me after I revealed it.”

He mentions the idea of using a circular arm came up after failing to find a good solution with pumps and tubes.

I tried to make a system that used multiple pumps, valves and bottles, but it was a failure. I didn’t touch the project for over 3 years, then came back to it when I had the idea of making it a dip-and-dunk style machine (moving the film to the chemicals, instead of vice versa). I design everything in 3D and can make quick iterative improvements because of my reliance on 3D printers. – Matt Bechberger, Reveni Labs

The reliance on 3D printers and parts makes the Dunkbot easy to maintain and produces minimal waste in the manufacturing process.

Film is loaded into a light-proof film tank which attaches to a 2-axis crane-like robotic arm. The robot arm then moves the film tank through the various chemical baths based on the times, temperatures, and steps input into a controller. Cleverly designed, the film tank lets air flow in through the top and liquids through the bottom with light traps on both ends.

The controller is an “off-the-shelf Raspberry Pi Pico microcontroller” which is easily replaced using a socket installation. Additionally, it can be updated through a micro USB connection to a computer without needing any specific software. Reveni Labs promises all software or feature updates will always be free.

Regarding timing, the Kickstarter aims to be in the final stages of kit preparation and shipping by September 2023. Options to back the project include self-assembly with a kit or having the Dunkbot come pre-assembled.

To back the Kickstarter or find out more information, head over to the official campaign site here!

Share this post:

Comments

Jim Hofman on NEWS: The Dunkbot from Reveni Labs Automates Processing Film At Home

Comment posted: 06/03/2023

Graham Orbell on NEWS: The Dunkbot from Reveni Labs Automates Processing Film At Home

Comment posted: 06/03/2023

Ibraar Hussain on NEWS: The Dunkbot from Reveni Labs Automates Processing Film At Home

Comment posted: 06/03/2023

Michael J on NEWS: The Dunkbot from Reveni Labs Automates Processing Film At Home

Comment posted: 07/03/2023

Castelli Daniel on NEWS: The Dunkbot from Reveni Labs Automates Processing Film At Home

Comment posted: 07/03/2023

Our teacher used s/steel tanks. He had a machine shop slice off the bases of his tanks. He then had s/steel covers welded to the base of the tank. They were light tight. His processing chemistry was placed in large sheet film developing tanks. The film was loaded, capped with the small fill covers removed. He had a homemade dip & dunk system. He dropped the loaded tank into the chemistry, and processed the film. I remember this because it was my Dad who modified the tanks, and my uncle who brazed the bottom lids on the tanks. The price? The local photographer agreed to teach me darkroom skills!

Comment posted: 07/03/2023

Martin JONES on NEWS: The Dunkbot from Reveni Labs Automates Processing Film At Home

Comment posted: 07/03/2023

Scott Gitlin on NEWS: The Dunkbot from Reveni Labs Automates Processing Film At Home

Comment posted: 10/03/2023

Matthias on NEWS: The Dunkbot from Reveni Labs Automates Processing Film At Home

Comment posted: 14/03/2023