The tantalising mysteries of microfilms (AKA ‘copy’ or ‘document’ films) grabbed my attention almost as soon as I re-entered the world of film a few short years ago, precipitated by my desire to renovate and test drive my late grandfather’s ancient No.1A Autographic Kodak Junior. While I shot quite a lot of film in the pre-digital era my usage was limited to a fairly narrow range of types (mainly colour transparency), so I am now kind of curious to learn about some of the species I never went near back in the day. Microfilms, which have a much deeper and more intriguing history than I ever imagined, promise great riches in terms of detail resolution and fineness of grain but these need to be unlocked with special keys in the form of ‘soft’ or ‘compensating’ developers so that a decent gradation of tones can also be achieved. After all, microfilms are designed to reproduce pages of text in black and white with no grey, which is exactly what you get with ‘normal’ developers. You can actually get reasonable results in many cases with stand development in Rodinal but here I want to showcase a unique developer that is very cheap and works well but doesn’t seem to have a big following.

H&W Control gets a brief mention at the bottom of page 134 of Bill Troop and Steve Anchell’s ‘The Film Developing Cookbook’ (2nd Edition) but they don’t give any detail about it other than to say it was the ‘first commercial document developer’. There are a handful of web sites – e.g. here and here – that provide the recipe (and suggested development times and agitation regimes). The key feature of this formula is that it uses phenidone and hydroquinone in a super-additive combination, but the actual total amounts used are extremely small and thus highly economical. It is far more stable than POTA (which is also good for microfilms but has a lifespan of two hours once mixed) and from what I have read (and seen in practice) gives quite a bit more speed.

I understand this developer is named after Harold Holden and Arnold Weichert, who arrived at the formula in the late 1960s and offered it for commercial sale in the early ‘70s in combination with Agfa Copex Pan Rapid microfilm (presumably the immediate ancestor of the film I am using here). It also became popular with other microfilms and with Kodak’s Technical Pan film, which is no longer available but still has a bit of a cult following.

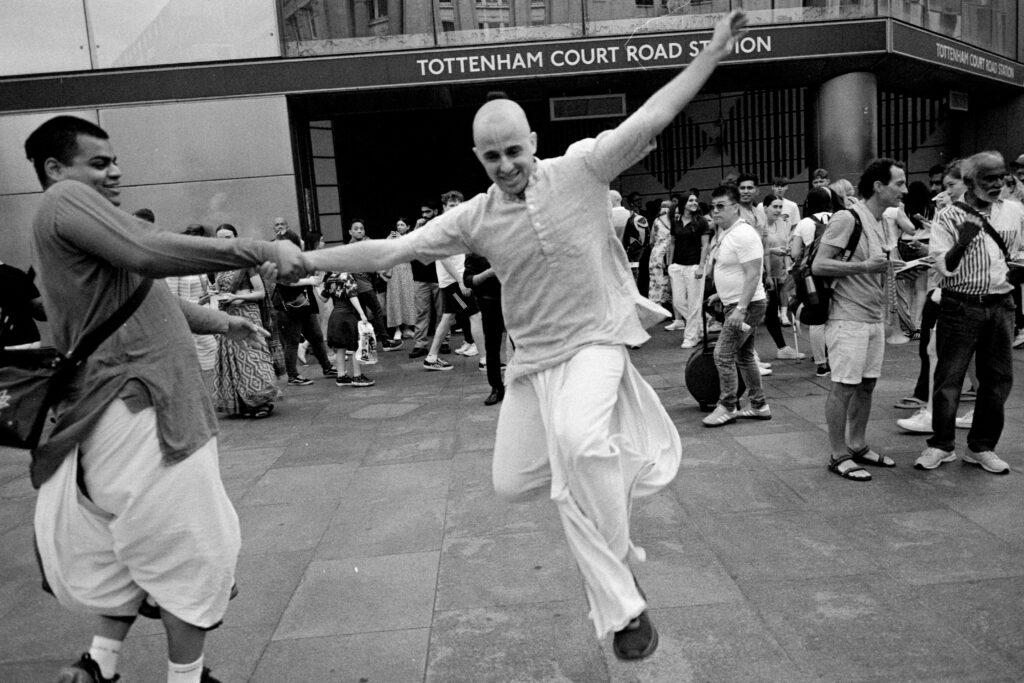

The below five frames are my initial foray into this arcane but fascinating world of document films, and I hope to share more results with this and some other nifty developers using Copex Rapid and Adox CMS20 II as well as Rollei’s wonderful Retro 80S in a future post. The camera used for the pics below was a Nikon F801S with an AF Micro Nikkor 60mm F2.8 lens. I bracketed between 50 and 25 ISO (the film is supposed to be rated at 50) and most of the better shots were the ones exposed at 50. The film was processed for 11 minutes at 20 degrees centigrade with gentle agitation for 30 seconds at the start and then for ten seconds every three minutes. I used two 30 second rinses in distilled water instead of an acid stop bath, and I fixed it in Ilford Rapid Fix for 4 minutes at 20 C. I pre-soaked the film in distilled water for a minute before development. Negs were scanned with a Nikon Coolscan LS9000 ED @4000DPI using Vuescan software.

Images 1, 2, 4 and 5 were made on Wulgurukaba Country, and Image 3 on Bindal Country, North Queensland, Australia.

Many reviews of microfilms advise rating them at least a stop slower than ‘box speed’ (especially when using ‘normal’ developers like Rodinal, Xtol or HC-110 at high dilutions) so I had bracketed most shots to ISO25 as a precaution. H&W Control is widely reported to be ‘speed-enhancing’. But further tests I have made suggest that H&W Control isn’t so speed-enhancing that you can rate Copex Rapid at higher than 50 – those images tend to have a lot of blocked up shadows, despite good mid-tones and good detail in highlights. It is possible that longer development times with less agitation may help capture more detail at both ends but I have not done enough testing to know this. To be honest I don’t enjoy testing films and really only do it out of necessity, when the information I need isn’t in the public domain already.

A quick note about mixing H&W Control. Dissolving the phenidone in an alcohol (methanol, ethanol, isopropanol – doesn’t really matter) or a glycol makes the process much easier. You can mix this developer as a one-shot solution if you have digital scales that go to milligrams or you can make a stock and mix your working solution from that. I store my stock solution in the fridge in mylar pouches, which you can squeeze all the air out of and which I understand are impervious to oxygen so can be stored for longer (I do the same for Xtol).

Copex Rapid is fabulously sharp and detailed, though with some grain detectable at high magnification. The images I have made with it on medium format look as though they could make very large prints if desired. It is now quite difficult to find in Australia.

I hope this has been of interest or use to some. My Flickr page is here.

Share this post:

Comments

Dave Powell on Agfa Copex Rapid developed in H&W Control

Comment posted: 14/12/2023

Comment posted: 14/12/2023

Murray Leshner on Agfa Copex Rapid developed in H&W Control

Comment posted: 15/12/2023

Thank you.

Comment posted: 15/12/2023

Geoff Chaplin on Agfa Copex Rapid developed in H&W Control

Comment posted: 24/07/2024