In no way, shape or manner this should be construed as a professional review, for it is not. Just my personal opinion on this 8×11 film developing reel, recently purchased. That said, do enjoy!

I have been a user of Minox 8×11 cameras since the mid 90’s, and I always developed my own films in a Minox daylight developing tank, since my first 8×11 negative. Never felt the need or desire to change this, Minox tank was and is a beautiful tool to process this tiny film format. And trying to experience the whole Minox thing as it was intended by Zapp: vintage camera, vintage meter, vintage flash, vintage tank, vintage film wallet… you understand.

That said, I had a change of mind recently. While processing some film in a very diluted developer, some 1+100, I noticed that the film came out undeveloped partially. The top half of it was clearly not completely developed, although I agitated the tank as per regula. And the second film followed suite, in the same manner, and the third one as well, all in the same conditions and dilutions as above. I have tried the pumping and dripping, pipettes and other implements, no luck. All underdeveloped, all on the top half of the Minox inner reel, all annoying results. Something was wrong here, and I knew what it was: uneven dispersion of the developer. Seen it before, know what it is, fought with it over the years, lucky at times, sometime not. Could there be a better way to do this?

Mind, I do not develop very often at that dilution; usually, my developer goes anywhere from stock/1+1/9/14 to 1+50/75 max. Of course, there are many variations, but generally I keep my processing inside these dilution limits, and it all depends on the type of developer, film, shooting circumstances. I had troubles in the past with this film, or that developer, but usually these situations are rare, and they are easily redressed. However, this high dilution failure made me think of alternatives. And such one is this 8×11 developing reel.

Now, I am not a complete stranger to developing Minox film on a developing reel. In the late 90’s, I borrowed a Honeywell Nikor steel reel from a photographer friend and experimented with it. That poxy thing was particularly annoying in handling, difficult to load, slippery, clinking and rattling in the tank (which was steel as well), and gave me a general feeling of using some kitchen implement. Many have used it with success, and swear by it, but for me it was an unpleasant experience. I have returned it in a hurry to my friend, thanks but no thanks, and never thought about trying one ever again. Well, you know what they say: “Never say…”

So I thought to try this type of dev reel, with the only intent of attempting the complete immersion of the film in the developer, and see if it behaves better. Processing the Minox film in a dev tank using this sort of implement is something that others are doing with more or less success. Finally, I placed my order for a couple of these items.

Right, let’s have a shufti then.

The items came well packaged, between two sheets of sturdy cardboard, and wrapped carefully, the entire thing in a heavy duty 3M envelope. It was clear to me that the seller took every step to ensure the reels will arrive safe at destination. You can tell a few things about a seller right from the start, upon receiving the package. If the package is well made and shows responsibility and care to the customer, it’s a good start.

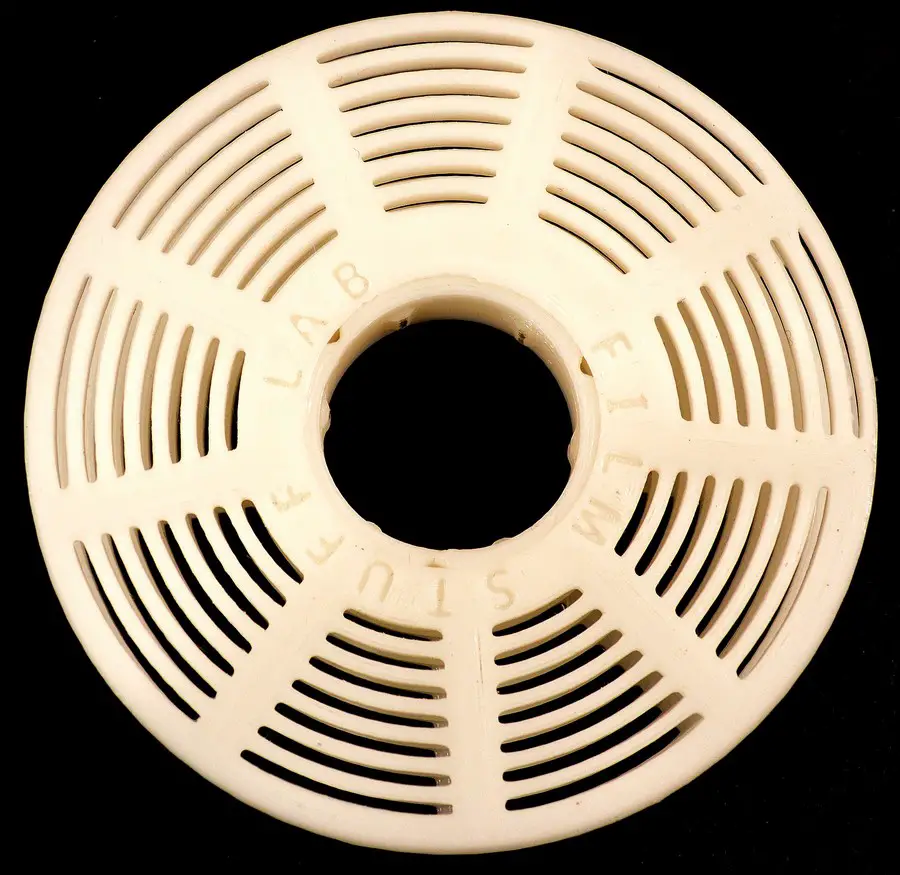

This reel is 3D printed by Jim Anderson of Film Stuff Lab, who makes these in support of the Minox community out there. Good quality plastic, from the look and feel of the thing, and when handling it, the reel feels quite solid and well made.

Although 3D printing leaves some surplus of material on the item after printing, these are cleaned up really good, smoothed out, and the reels I’ve received are a pleasure to hold and handle. One can clearly see the care and amount of work put into the final product. The entire perception of these items is that they mean business.

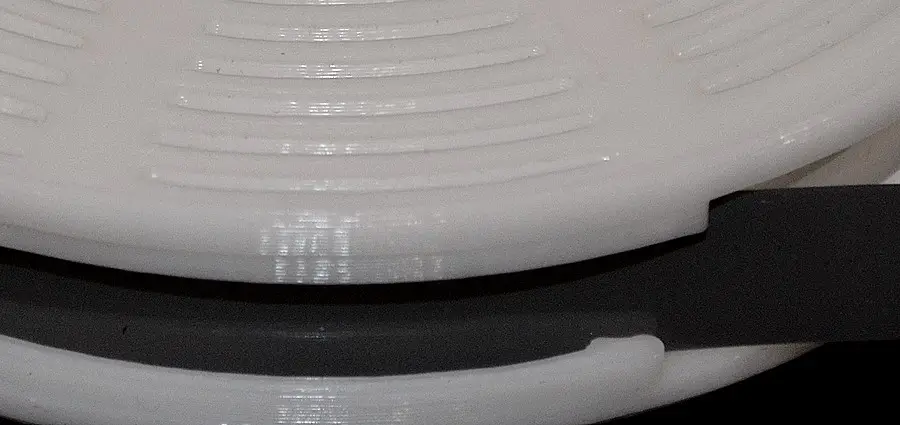

The outer diameter is 85mm, the inner diameter is 25mm. Width of the reel, measured from outside the flanges, is 15mm, with 10mm for the inner track width. The film width best used in this reel range from 9.20mm to 9.50mm, and the film is held within the inner track by solid and smooth flange skirts. It could be possible to insert other widths of Minox film in, but I have tested this reel with only those two film widths. Anyway, as Minox regular film is 9.2 – 9.3mm (with the odd presence of some 9.5mm film on the market), this reel should behave all right.

Thickness wise, there is plenty of room for even the thickest negative, if need be. Of course, the film thickness vary, as you all now: some 35mm negatives are thinner or thicker than say 120 ones, but I do not believe any of the 8×11 film you would cut from either of these stocks will present a problem for this reel.

The reels I bought were specifically designed for use in the Jobo tanks, and that is clearly indicated in the materials and on the reel too, but they are also offered in configurations for Paterson and Stainless Steel tanks too. Indeed, the reel feels comfortable in my Jobo 1510, with some room to spare. Both of the 8×11 reels are 30mm in height, when stacked. The Jobo 35mm reel is almost 40mm, and this means the volume of the developer needed to process two Minox films at once is some 200ml for inversion processing.

For rotational processing – something that Jobo excels at and is designed for – then the amount of chemicals can be much less depending on the tank you are using. So for inversion style processing, this quantity of developer is almost 3 times over the regular solution required for the Minox tank (65ml). Oh well, such is life, you get some, you lose some.

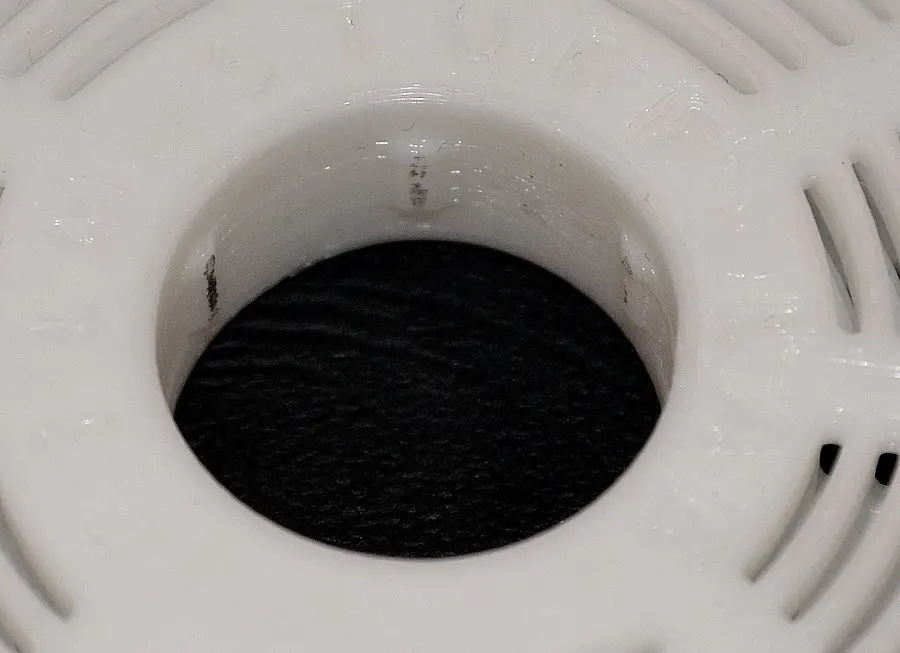

The core of the Jobo tank fits the reel really good, and with two of these reels in place, the rattling in the tank is non-existent. The protrusions in the inner core of the reel keep the reel snug and tight. One does not have to force the reel onto the Jobo core, just slip it on, it hugs the core really well.

Loading the film is a breeze. As per Jim’s good advice, one has to clip the corners of the film leader, to ensure a smooth propelling the negative through the reel’s tracks. Not rounding them corners, just clipping a tiny bit of each. Many of us who process their own 35mm negatives already do this, but it is always great to be reminded. Just insert the leader onto the rails, and slowly keep pushing the film, taking care not to touch the emulsion side. The emulsion side in the inside of the reel, and this helps keeping the film into place, because of the eccentric force of the film curvature. It pushes into the tracks, holding it nice and close.

The reel can be loaded using either of these two methods: push the negative through, or employ the loading method of Paterson/Jobo 35mm reel, by friction loading. The 8×11 reel has two modes or settings, if you like: a fixed one, where the two halves are fix (for when you are pushing the film), and a mobile position or mode, where you push the film leader in and twist the two halves, advancing the film inside the reel, as per classic 35mm reel loading. These two modes can be deployed by twisting the halves from fix to mobile and back, very easy. The inside locking mechanism is reliable and does not slip; just make sure you have locked the halves in the desired position. Each position is indicated by a reassuring click, when locked into that mode.

For those who are accustomed to using a Minox daylight developing tank, there is however a downside: the reel needs to be loaded in darkness, and this of course is a completely change of tack. Given the tiny size of the reel, of the negative and of the Jobo 1510 tank, this is easily done in a regular size change bag, no need of a darkroom. And anyways, one should not be afraid of the dark, for Minox users who cut their own films are very well acquainted with the dark.

Main pros?

- agitation and up turning the tank is a plus, for the Minox tank cannot be used in such a way

- loading the film like on a 35mm reel is much easier for those who never used the Minox tank

- The seller offers them in different compatibilities/configurations, for the main three development tank systems. There are versions for Paterson, Jobo, and Stainless Steel/Nikkor tanks

- one can develop 2 or 3 films at once, which is a brilliant method of fast process

Cons? I can’t think of any right now, haven’t identified anything amiss with this reel. Re built quality, I do hope the internal locking thing will not wear soon. Other than that, good to go.

This reel (and some of the other less common film format dev reels) can be purchased from seller’s online page.

Share this post:

Comments

Bob Janes on 8×11 film dev reel for Jobo tank

Comment posted: 16/06/2023

It sounds like we went in opposite directions, as I started out with a reel and gravitated towards the helter-skelter tube model – but notable that we both tried the other option because of partial development of negatives – in my case I could work out that the flanges of my reel were stopping the developer reaching the emulsion side of the negative. What I can't work out is why you were getting partial development with the Minox tank.

It looks like the tank winds the film onto the spiral core with the emulsion outwards where the developer can get to it, but I can’t see why that would leave you with the top half of the film undeveloped…

It may be that I'm interpreting 'top half' in the wrong way – I'd originally thought that each negative had the bottom half developed, with the top half not (or less so), but looking at how the Minox tank works I wonder if you mean that the shots that were lower in the tank were developed (presumably the end of the roll?) while the early shots did not get in contact with the soup… Presumably there was a diagonal band delineating developed and undeveloped shots?

Notable that the reel development problems I had in a Patterson tank were also with quite dilute developer. I also note that the Minox tank uses such small amounts of developer that using a 1 100 concentration must involve less than 1ml of concentrate, which must be tricky to get right...

Julian Tanase on 8×11 film dev reel for Jobo tank

Comment posted: 16/06/2023

The developer was all right, fresh and clean. The issue is (I believe) the high dilution, for other dilutions (up to 1/50) work just fine. I admit one or two badly developed films, but when this number exceeds two, then I call it an issue and stop doing that until I figure out what the heck gives here.

Yes, the tank takes only 65ml of solution, so when develop at 1/100, then the amount of developer is way less than it should be. I understand this and this is the main reason why I seldom use this dilution with 8x11 format; that said, never had any troubles with 35mm or 120 using say, Rodinal 1 100.

So, yes, it is still a work in progress, but the Jobo reel I am speaking of here is doing a great job. It is liberating somehow not to think of possible bad results when developing a film. This reel helps me doing that :) .

Thank you for your comment, really appreciated !

Comment posted: 16/06/2023

Comment posted: 16/06/2023

Castelli Daniel on 8×11 film dev reel for Jobo tank

Comment posted: 17/06/2023

Seriously, it’s nice to find people working to keep systems going.

As a side thought, does anyone remember when Ilford made 72 exposure HP-5 (4?)? It was made for 35mm cameras w/motor drives.

Hewes made a standard diameter reel that would accommodate the long rolls. Thin plastic based film. We bought some for our school photo dept.; took forever to load, and we recruited one of our TALL b/ball players to hang the film to dry. Never tried that film again!

Julian Tanase on 8×11 film dev reel for Jobo tank

Comment posted: 17/06/2023

https://www.etsy.com/shop/FilmStuffLab

Mr Canary on 8×11 film dev reel for Jobo tank

Comment posted: 20/06/2023

I've now got my own method of developing Minox and 16mm film now that is cheap. I'll contact 35mmc to see if they think an article is worthwhile.